How we recycle metals at Umicore

“Take-make-dispose” is out of fashion. People are increasingly concerned about the environment and want to save materials, reduce pollution and eliminate waste. This means consuming differently by keeping products and materials in use for as long as possible, which is where recycling plays a crucial role.

Unlike other raw materials, metals are perfect for recycling due to their permanent characteristics. In other words, since metals do not lose their chemical or physical properties during recycling, they can be used and re-used infinitely while maintaining their quality and functionality. However, recycling of metals can be very complex depending on the material components of the source of the waste stream.

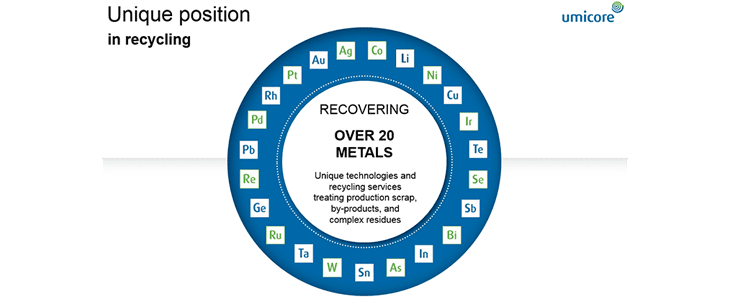

28 different metals

At Umicore, we recover up to 28 different metals through two types of recycling operations. Our recycling operation in Hoboken, Belgium, is built to recycle and refine the most complex materials and to recover a broad spectrum of metals. Our other recycling operations recover metals mainly from production residues.

Complex materials means electronic scrap (printed circuit boards, cell phones and other small IT devices), spent rechargeable batteries, and industrial residues as well as other material streams, as they all contain a wide range of different materials, including hazardous substances. We are a global leader in recycling because our unique and innovative metallurgical processes result in maximized metal recovery rates generating optimum metal yields. Additionally, our installations follow strict environmental procedures and safely eliminate hazardous substances.

How does it work?

In a very simplified way, metals have different interactions and affinities with other metals in metallurgical processes due to their different physicochemical properties. Base metals, such as copper, lead and nickel act as collectors of precious and other metals, thereby facilitating the recycling of those metals. For example, because copper has good compatibility with many precious metals such as gold and silver, it facilitates high recovery rates of those metals which are then refined through further multi-step processes. We also use similar steps to recover germanium from a wide variety of sources including fiber optics, solar cells, LEDs and infrared optics.

Recycling is the key component of our closed loop business model. We turn waste into resources for our customers, as well as for our own production, giving us a greater competitive edge and contributing to reducing environmental impact. Recycling provides a highly efficient way of reintroducing valuable materials back into the economy and tackling key strategic challenges. Because metals are such essential components in key sustainable innovations, including low-carbon transport, renewable energies and digital communications, recycling plays an important role in increasing resource efficiency.