Quantitative comparison of the chalcogenide glass GASIR with Germanium and Silicon for use in LWIR sensor lens design

This text is an online preview. The full version is available as a PDF download.

The cost of a lens is to a large extent determined by the number and complexity of the optical components. Requirements such as resolution, focal length and f-number drive the size and number of elements. This is true especially for imaging optics, but with the rise in pixel count for sensing detectors it is becoming increasingly valid for sensor lenses as well.

Another key determinant of both design and price is the material being used. Germanium lenses have long been a favourite of the infrared lens designer due to the high refractive index, but suffer from drawbacks such as thermal drift and price fluctuations. Chalcogenide glasses have been developed to overcome these limitations, albeit at a lower refractive index. Where resolution is not as critical (i.e. for detectors with few pixels), silicon lenses are widely used.

A representative quantitative comparison between germanium, spherical silicon and GASIR for long-wave infrared sensor lenses is shown below and takes into account such parameters as field of view, f-number, MTF, lens size and energy throughput (ETP). The latter parameter is defined as the transmission of the entire system scaled by the square of the reciprocal of the f-number:

ETP = τ/RF2.

| Germanium | Silicon | GASIR | |

|---|---|---|---|

| Focal length | 1.8mm | 1.9mm | 1.7mm |

| Total track length | 7.5mm | 9.6mm | 5.4mm |

| Aperture-based f-number RF | 1.00 | 1.25 | 1.03 |

| DFOV | 135° | 134° | 136° |

| Lens dimensions

(thickness x diameter) |

4.4mm x 4.4 mm |

3.2 mm x 3.2 mm 4.0 mm x 4.0 mm |

2.6 mm x 3.5 mm |

| Energy throughput | 0.94 | 0.40 | 0.86 |

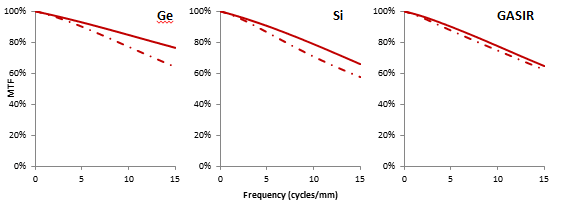

On-axis MTF (full line) and MTF at 70% field height of a 160x120 17 µm detector (dash-dotted line). X-axis cutoff is half the Nyquist frequency.

The following trends can be seen: Germanium lenses tend to have good resolution, but suffer considerable thermal drift and the lenses are quite large and thus costly. Lenses in spherical silicon yield no practical results, as despite resolution being acceptable, thick lenses and a smaller f-number lead to energy throughput that is too low for sensing applications.

GASIR lenses, on the other hand, trade off a more compact design for slightly lower resolution. This, together with intrinsic material properties such as moldability and thermal stability, allows for a cost-effective solution with superior performance.

(JV, NS, JF)