Cobalt

Did you know that cobalt was the first metal to be discovered? Cobalt minerals have been used as pigments since ancient times. Although not under the name cobalt, the metal was used to color ceramics in Persia and Egypt. Today, it has many other applications and different uses, such as in medical solutions and in the battery industry. You might even recognize several of it applications. Cobalt compounds and oxides are used respectively as catalysts and in the petroleum industry, meaning many of our means of transportation are related to this metal. Paints, varnishes and inks contain organic carboxylate salts of cobalt which triggers the drying effect of such products (are used to make paint dry). Other organic derivatives are involved in the rubber industry. Umicore also delivers cobalt products to the agro-industry and the three main applications that can benefit from our products are:

- Animal feed: cobalt is an essential compound in the animal feed industry, where it is a building block and promotor for the synthesis of vitamin B12 in ruminants such as sheep and cattle

- Fertilizer: cobalt is added in fertilizer used on meadow on which ruminants graze in order to induce B12 production

- Water treatment: cobalt can be added as a compound in products used for water treatment

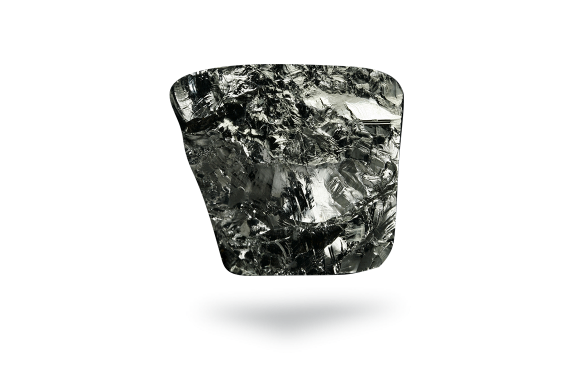

Umicore also offers an extensive range of cobalt oxides, ranging from high grade specialty oxide to lower grade alternatives that are able to meet the specific needs of each color application in the ceramics industry.

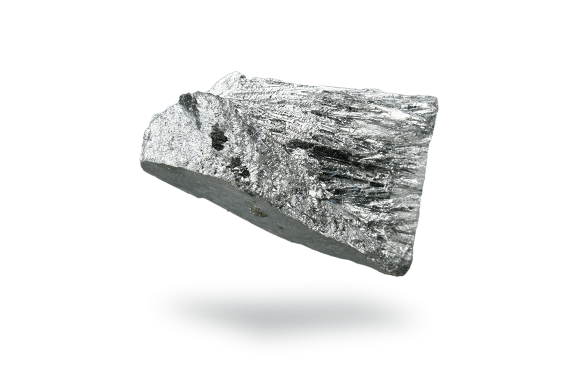

Umicore provides metal bond powders comprising of various types of cobalt powders and pre-alloyed powders (the Cobalite® range) used in diamond tools and hard metals.

Cobalt also has a very broad application in rechargeable batteries, mainly of Li-ion type. The incorporation of cobalt in the form of powder improves the electrochemical characteristics of these batteries. Cobalt along with lithium, nickel and manganese are the critical components in the cathode active material helping to determine how long you can talk on the phone, how far you can drive an electric car, how fast a battery recharges and how much energy you can store from your solar panels.

Recycling

Much of the cobalt is recovered from the production processes of manufacturers of applications like hard metal and cemented carbide tools or Li-ion rechargeable batteries. Cobalt can also be recovered from end-of-life products, such as spent rechargeable batteries, petrochemical catalysts and alloys used in aerospace applications.

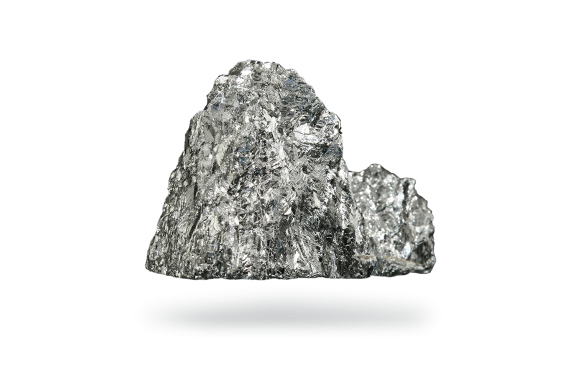

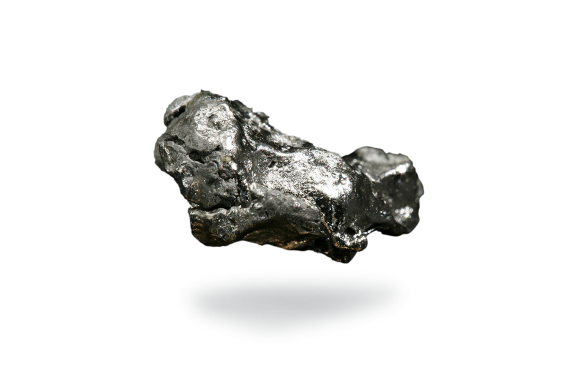

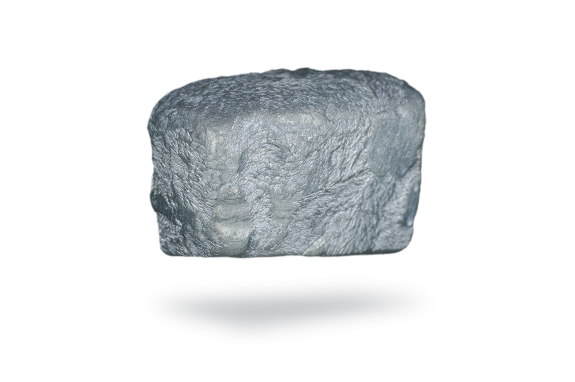

Properties

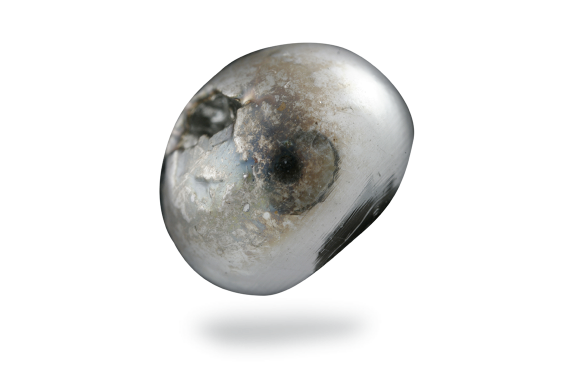

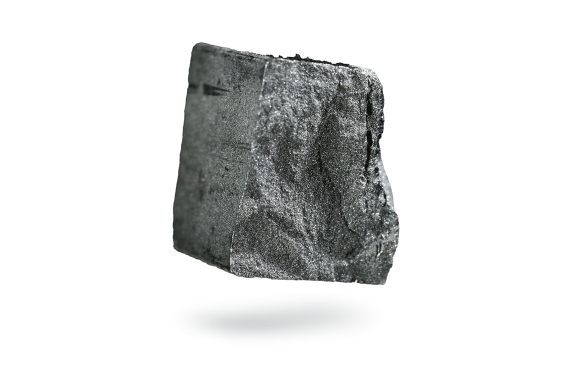

Cobalt is ferromagnetic which means it can become magnetized when exposed to an external magnetic field. This is especially useful when mixed with the right metals because it creates superalloys, materials that keep their strength during high stress and high temperatures. A good property for jet engines for example.

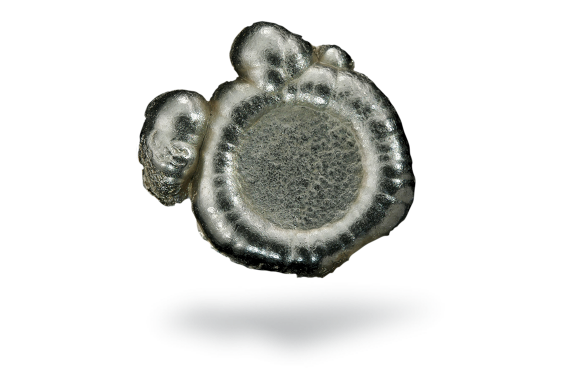

It crystallizes at room temperature in the close-packed hexagonal system (α–Co) and converts to the face-centered cubic form (β–Co) at 417°C. It is also bluish-grey metal, similar to iron and nickel. This is why so many ancient civilizations used it as pigment.

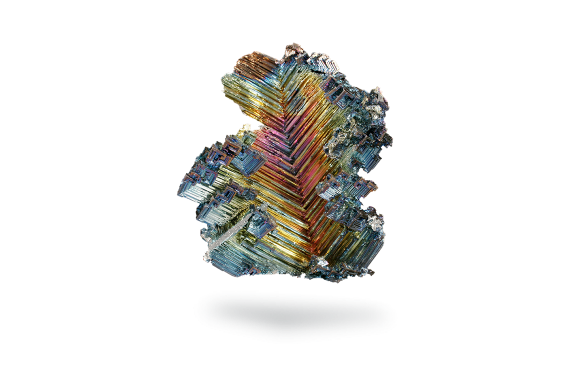

Cobalt blue

When melted together with sand, these roasted ores were converted into a blue glass called smalt. In 1742 the Swedish chemist Brandt showed that this color was due to an unknown metallic element, which was isolated in 1780 by Bergman. The pottery and ceramic industries were the only consumers of cobalt up to the beginning of the 20th century.

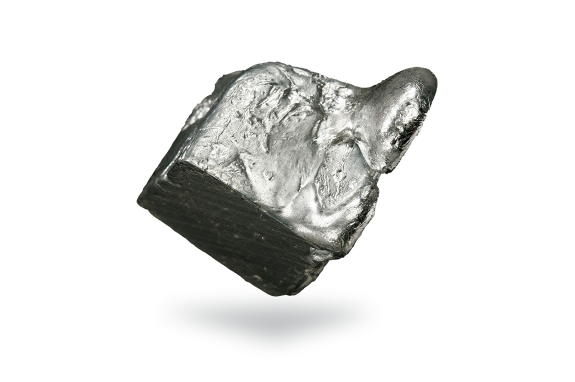

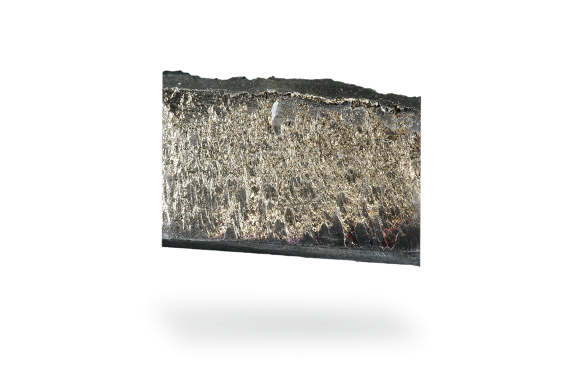

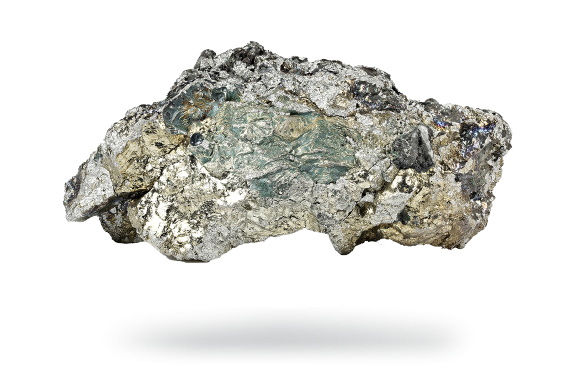

Extraction

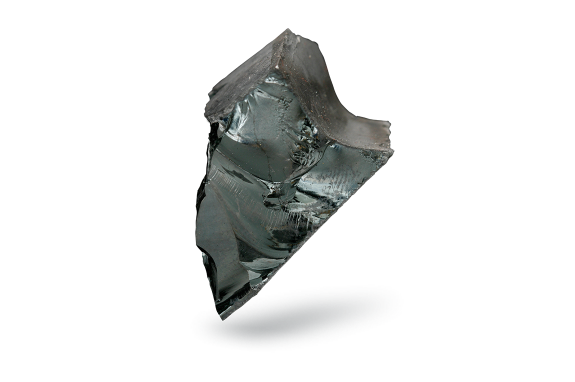

Cobalt does not naturally exist on Earth, but you can find it almost everywhere: the soil, in mineral deposits, and on the seafloor. Cobalt is always combined with other elements, such as nickel, copper, iron, or arsenic. It is usually collected as a by-product from the mining of other metals.

Sustainable cobalt sourcing

Umicore is the first company in the world to have introduced a Sustainable Procurement Framework for Cobalt and is the first to obtain external validation for its ethical procurement approach in this area. It aims to minimize the risk of any connection between the cobalt in its supply chain – and subsequently that of its customers – and human rights abuses or unethical business practices.

Find more about our Sustainable Procurement Framework for cobalt sourcing

History

In the 15th century, miners in the Ore Mountains (Erzgebirge) in central Europe used the term kobold for certain ores that were difficult to smelt. The name mainly referred to pesky, underground elves of local folklore, that were blamed for the difficulties of mining. Later it became the inspiration for the name of the metal.