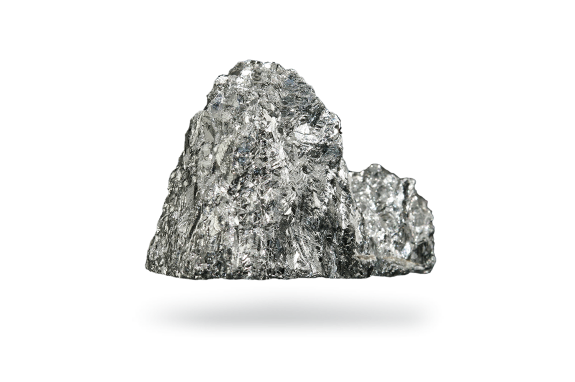

Bismuth

Bismuth was first used many years ago! The Incas combined this metal with copper and tin to produce knives and in Ancient Egypt, bismoclite was often used for cosmetic purposes. However, industrial production of the metal did not begin until around 1830.

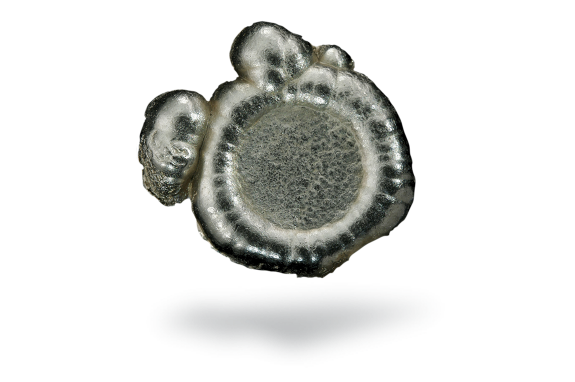

Today, bismuth is found in an application that is very useful to our local heroes. Can you guess who often uses this metal at work? Firefighters! Due to its low melting point, bismuth is used in fire detectors and extinguishers. So you probably have some bismuth in your home, ready to alert the authorities if fire breaks out.

Applications

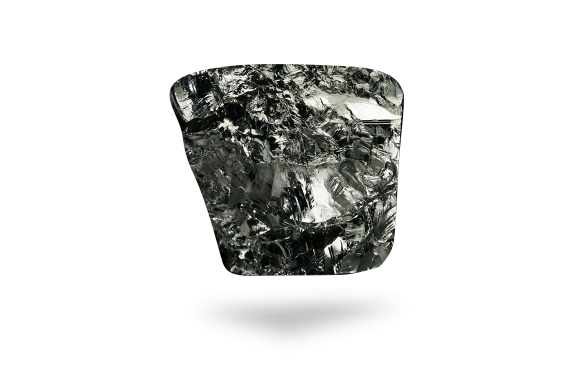

Metallic bismuth is used principally in alloys. However, it is also found in the pharmaceutical industry. A component called bismuth citrate is included in antibiotics that are effective against bacteria that cause stomach ulcers, for example. Bismuth is also found in other components linked to treating stomach aches, swelling or eye infections.

Due to its low melting point, it is used in electric fuses, solders and occasionally to make molds in the thermoplastic materials industry. Besides lighting your home, it can also add some color: about 300 tons of bismuth a year are used as pigments in paints. One of these produces the bright yellow colors used in the automotive industry.

If you don’t have enough color, you can apply a little highlighter. Many cosmetics, including eyeshadows, lipsticks and nail polish, contain bismuth oxychloride to give the products their pearl-like luster.

Recycling

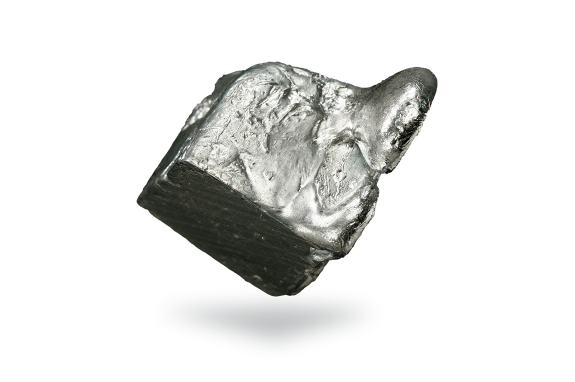

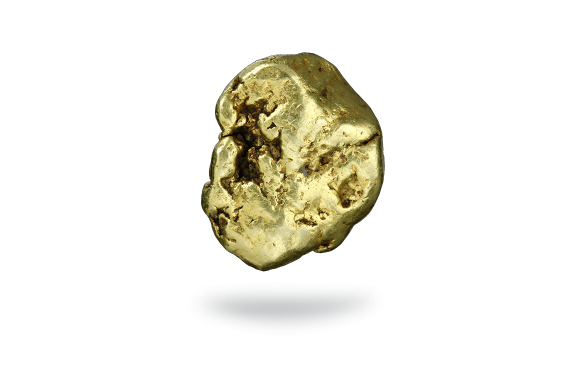

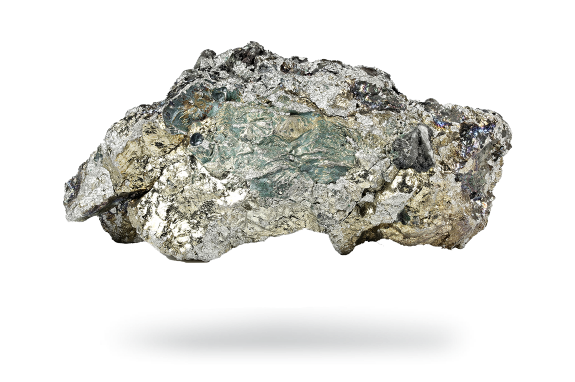

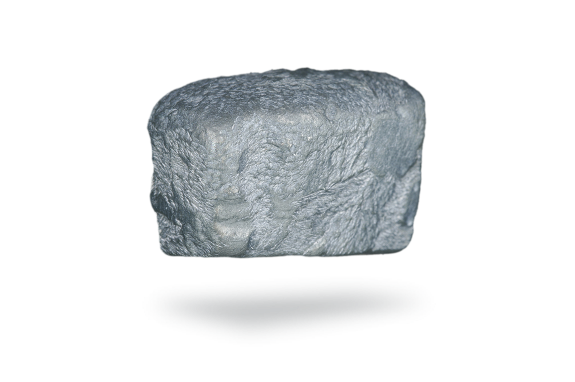

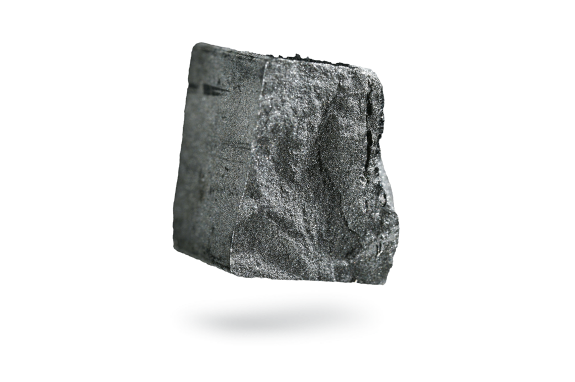

Bismuth is difficult to recycle because it is used in many dissipative applications, such as pigments and pharmaceuticals. It is recovered from the production processes for lead, copper, tin, silver and gold refining. At Umicore’s integrated smelter-refinery in Hoboken, Bismuth is recovered from the lead bullion exiting the lead blast furnace.

Properties

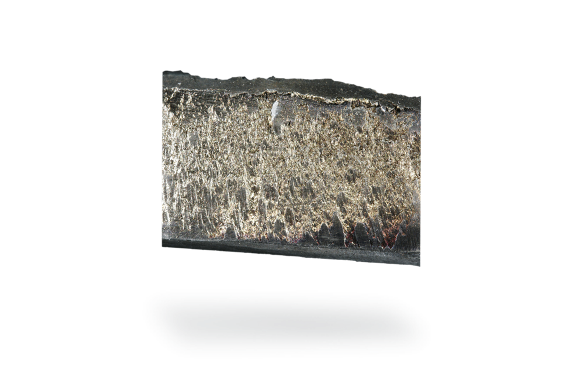

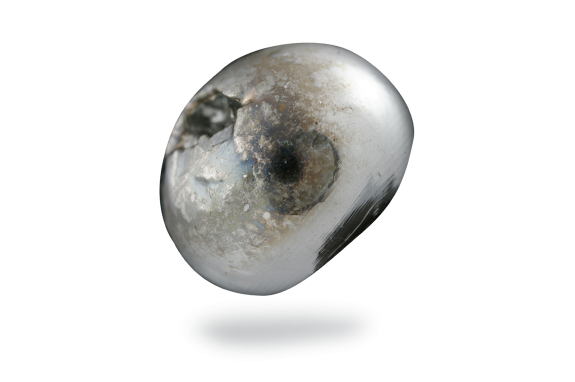

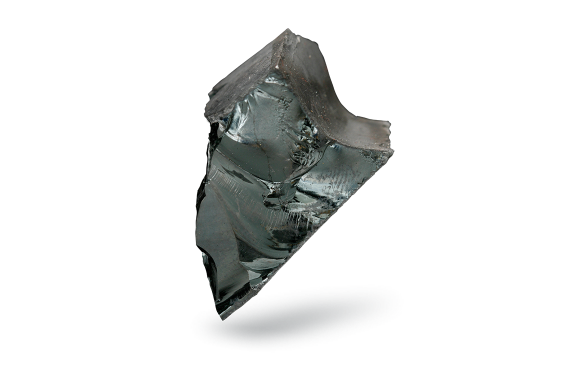

Bismuth is a hard, brittle, lustrous, metallic element with a pinkish tinge. It can be distinguished from all other metals by its color. Unlike most metals, its electrical resistivity is greater in the solid state than in the liquid state.

Naturally occurring bismuth is found in small quantities throughout Earth’s crust both as a pure metal and combined with other elements in various compounds.

History

In the 15th-century writings of the German monk Basil Valentine, this element is referred to as Wismut, a term derived from the German “weisse masse”, meaning white substance. It was Latinized to bisemutum by the mineralogist Georgius Agricola, who recognized its distinctive qualities and described how to obtain it from its ores.

The basic nitrate Bi(OH)2NO3 was used by painters in the 16th century and was known as blanc d’Espagne. Industrial production of the metal began in Saxony in around 1830.