Tin

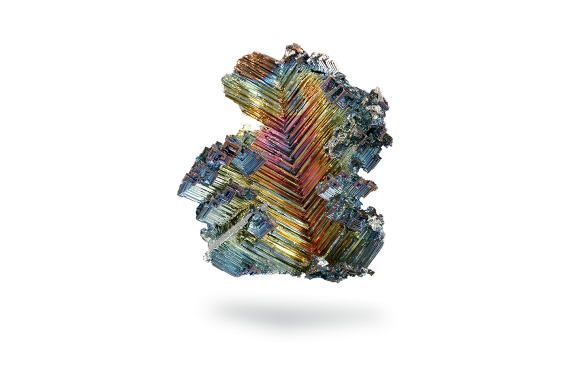

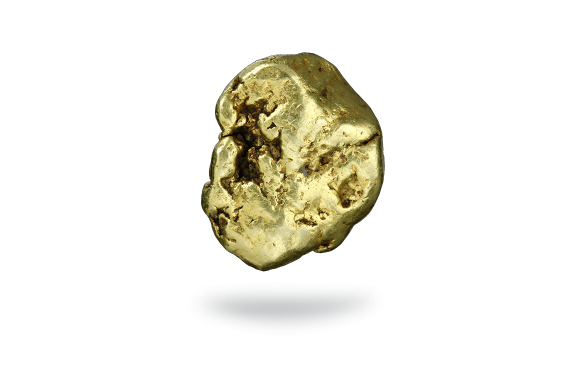

Any challenges or competitions coming your way? If you are participating in a science, sports, art or game competition of any kind, you might be on the podium and even end up with a gold medal. But you shouldn’t be too disappointed with 3rd place. After all, a bronze medal is great, too, as it contains tin, a Umicore metal. Tin is found in many useful alloys. Bronze is an alloy typically consisting of 12% tin and 88% copper.

But why is tin important in our lives? Well, it is a great way to package foods, for instance. In addition, and more importantly, it is used in lead-free solder formulations for electronic manufacturing, an application that accounts for about 50% of total tin consumption. It is set to contribute to the fourth industrial revolution and to the green industrial revolution.

Applications

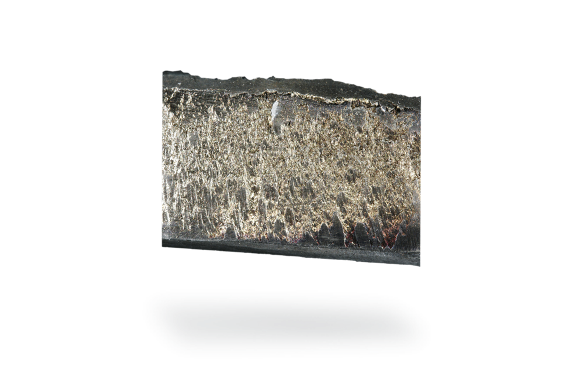

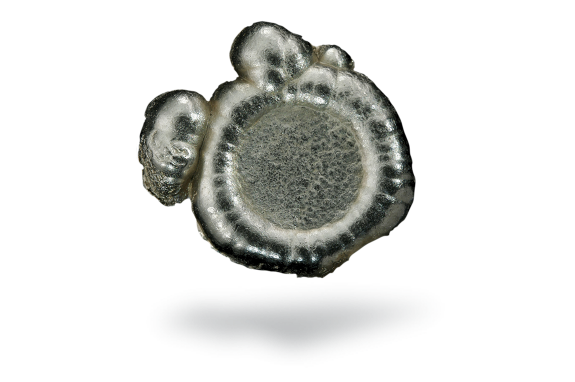

Tin has long been employed as an anti-corrosion coating for soft iron in the manufacture of food and beverage cans. A tin can is actually made from steel. A thin layer of tin is applied to the inside and outside of the can to keep the steel from rusting. This application currently accounts for about 15% of tin consumption. The protection provided by the coating is effective only if the layer is in perfect condition; the slightest crack or pit will lead to corrosion.

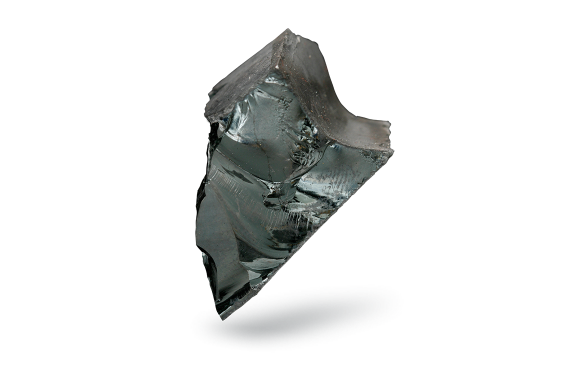

Tin–lead alloys are used for soldering, particularly in the manufacture of printed circuits that are found in many of our electronic devices. Its use here is bound to grow significantly in the context of the technology “super-cycle” (5G, Internet of Things, more smart devices, smartphones, etc.). It will also play an important role in clean mobility and green energy as tin units are used in electromobility and the related charging stations, and in wind turbines and photovoltaic panels, all of which require electronic components and wires. Tin can be also found in carbon capture catalysts and water treatment technologies.

An alloy of tin and niobium is used to make superconductive wire or magnets.

Tin alloys range in color from red through yellow to white, depending on the copper content. Bronze is found in springs, gears and bearings.

Other uses include organ pipes, glass-making to obtain a perfectly smooth surface, lead electrodes and lead-acid batteries, and as a replacement for lead in wine-bottle caps. Mixed indium–tin oxides are used as conducting coatings on certain glasses, such as those for windscreens to facilitate de-icing, and for LCD screens and touch screens.

Tin tetrachloride (SnCl4) hydrolyzes easily; it is used as a mordant and as a starting material for the preparation of organo-stannic compounds used, for instance, in agriculture and as stabilizers in PVC-type plastics. Tin oxide is also used for ceramics and gas sensors, while zinc stannate (Zn2SnO4) is a fire-retardant found in plastics.

Recycling

When tin cans are recycled, tin from the thin metal coating is recovered by electrolysis in a NaOH solution. Tin is also recovered from solder alloys and from manufacturing processes such as the production of targets containing tin for conductive coatings.

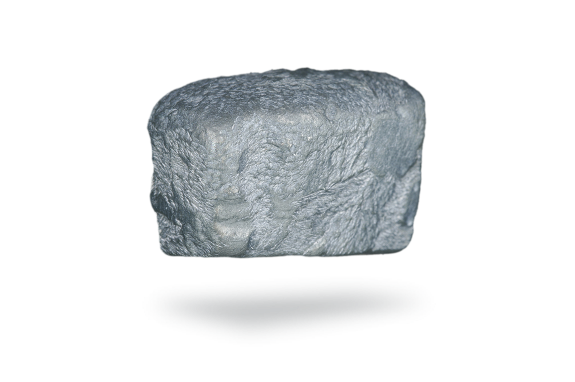

Umicore Precious Metals Refining recovers tin under the form of a (impure) tin salt (calcium stannate), which is then sold to the tin refiners of this world.

Properties

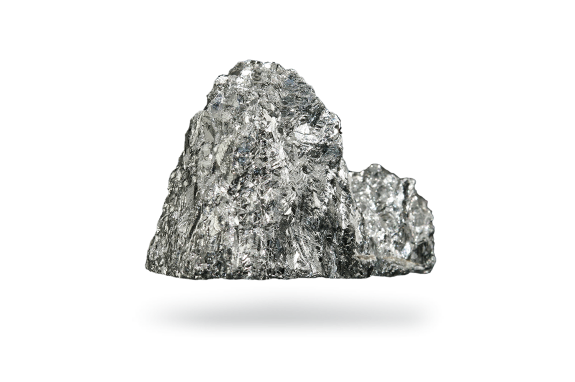

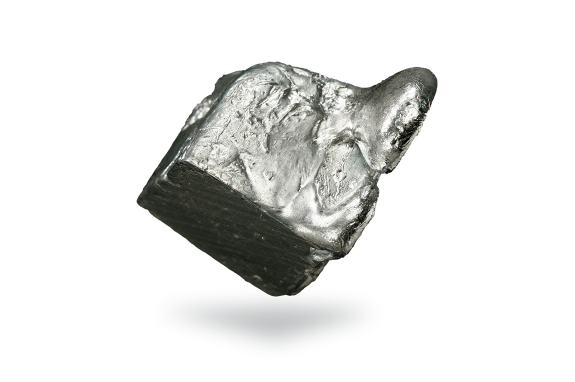

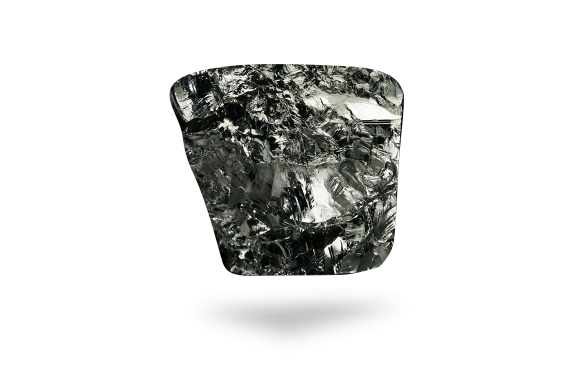

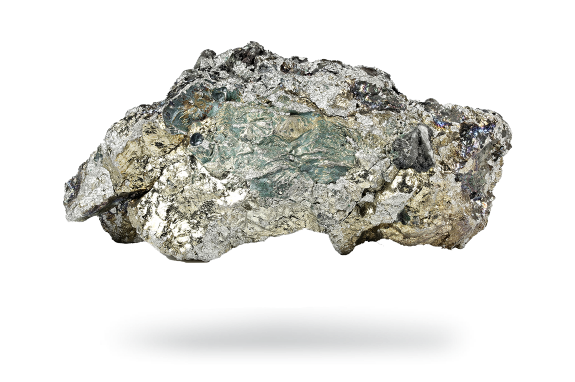

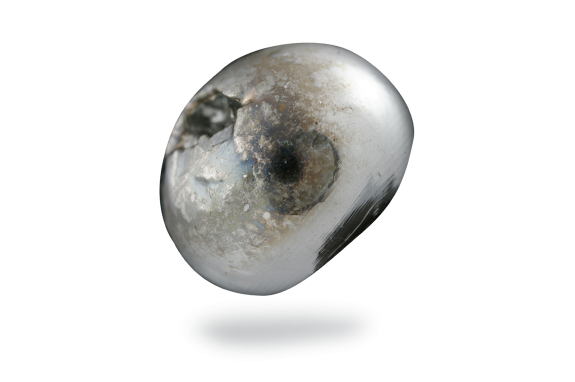

Tin is a soft, silvery white metal that is malleable, ductile and has a highly crystalline structure. Below 13°C, it slowly changes to a powder form. When a tin bar is bent, the sound made by the crystals as they deform can be clearly heard. This is known as the tin cry.

The β-Sn or white tin variety is stable at room temperature and crystallizes in the tetragonal system. It can be rolled into very thin sheets (tin foil). Upon expanding, the metal disaggregates, a feature that was formerly considered to be a disease known as tin plague.

History

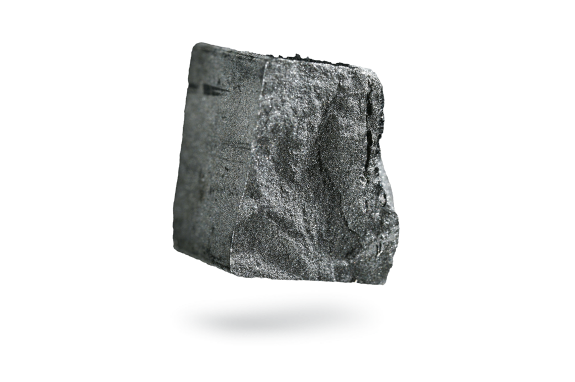

Tin has been known and widely used since the Bronze Age (around 3500 BC). Bronze, a copper–tin alloy, first appeared in the Middle East although there were no tin mines in that region, a fact that remains a historical enigma. Pure tin was produced in China and Japan around 1800 BC. Tin cutlery was frequently used in France around the 17th century, but such usage occasionally led to accidents due to traces of arsenic found in the metal.

In the early 19th century, Appert discovered that food products could be preserved in airtight vessels after being heated; this observation eventually led to so-called tin cans.