Praseodymium

Applications

- High-intensity permanent magnets, which are essential in electric motors and generators used in hybrid cars and wind turbines.

- Nickel metal hydride (NiMH) rechargeable batteries for hybrid automobiles. The negative electrode (cathode) in NiMH batteries is a mixture of metal hydrides – typically a rare earth misch metal hydride containing praseodymium, neodymium, lanthanum and cerium.

- An alloying agent with magnesium creating a high-strength metal for aircraft engines.

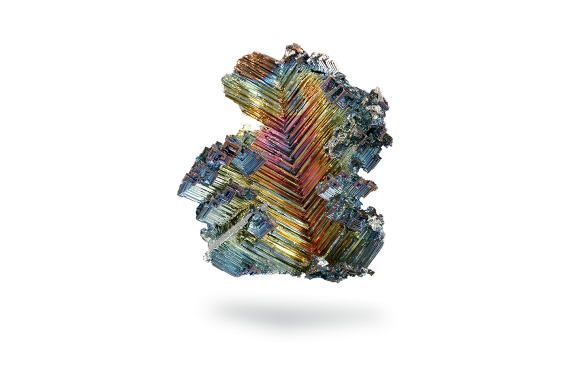

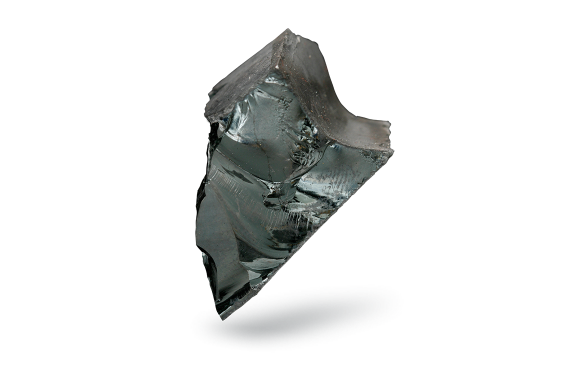

- Praseodymium is used to make specialised yellow glass goggles for glass blowers and welders. Praseodymium salts are used to colour glasses and enamels.

- Flame lighter flints use misch metal (a rare earth alloy) containing praseodymium to produce sparks by friction.

- Also used in the core of high-intensity carbon arc lights used by the film industry and in floodlighting.

- Colouring in ceramics.

Recycling

Rare earths are very challenging to recycle due partly to their very dispersed use.

Properties

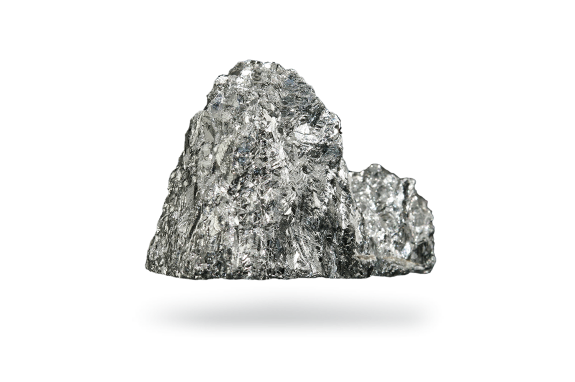

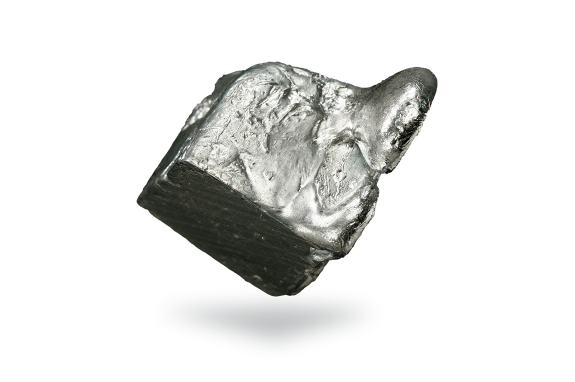

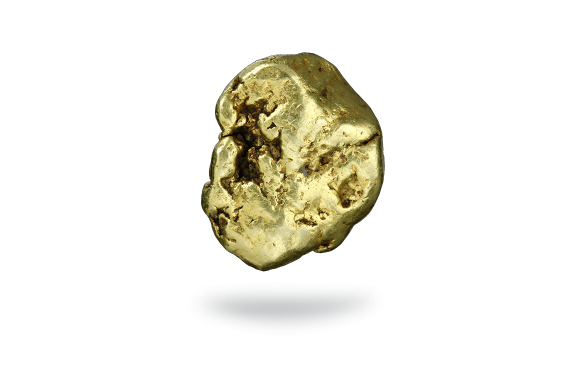

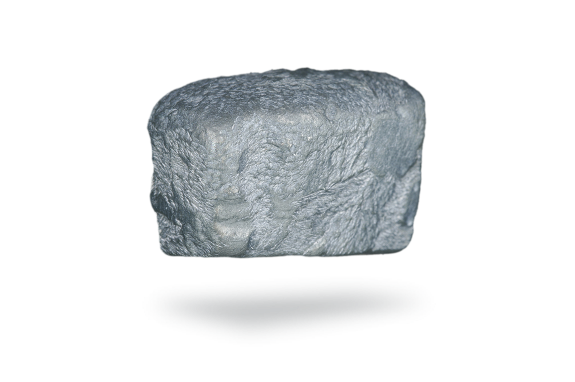

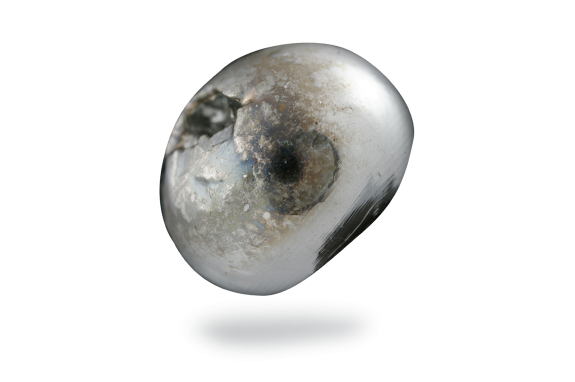

- A soft, malleable, ductile and highly magnetic silvery metal.

- Belongs to the lanthanide rare earth metals.

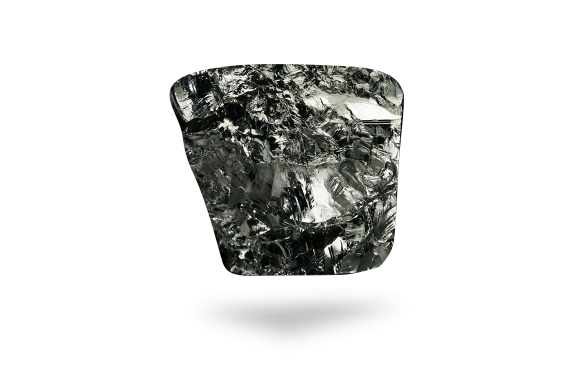

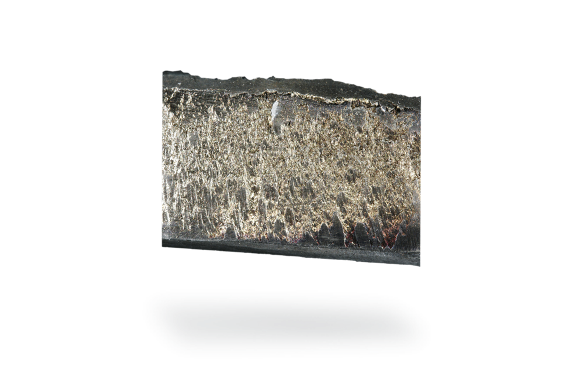

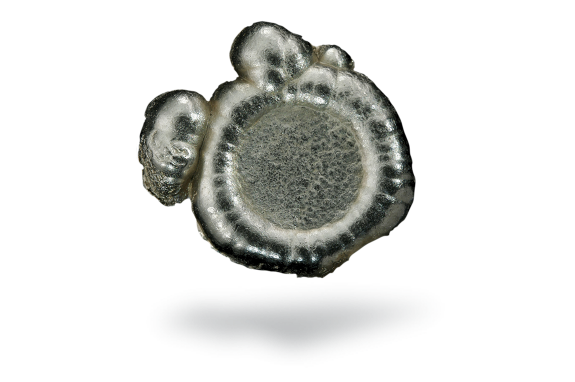

- Forms a flaky black oxide coating (Pr6O11) in air. Unlike many metal oxide layers, this one does not protect the metal from further oxidation.

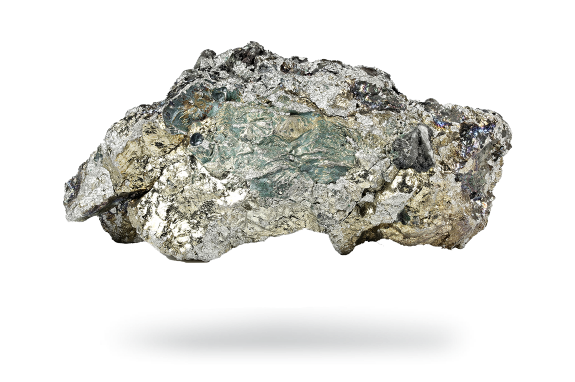

- The pale green sesquioxide, Pr2O3, is not stable in air.

- Praseodymium reacts with water to form praseodymium hydroxide plus hydrogen gas.

History

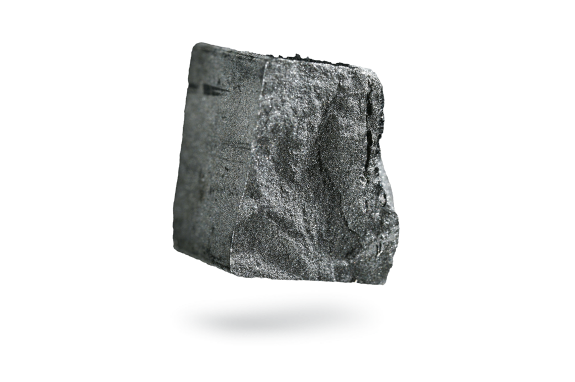

Praseodymium was first identified in 1885 by Austrian scientist Carl Auer von Welsbach. It was discovered in didymium, a substance incorrectly said by Carl Mosander to be a new element in 1841. Welsbach reacted didymium to form nitrate salts, which he then fractionally crystallised from nitric acid to yield greenish-brown praseodymium and pink neodymium salts. The fractional crystallisation experiments were very time consuming, involving more than one hundred crystallisation operations, each lasting up to 48 hours. Praseodymium was named using the Greek words prasios didymos meaning ‘green twin,’ reflecting its green salts and the close association with neodymium.

Pure metallic praseodymium was first produced in 1931.