Molybdenum

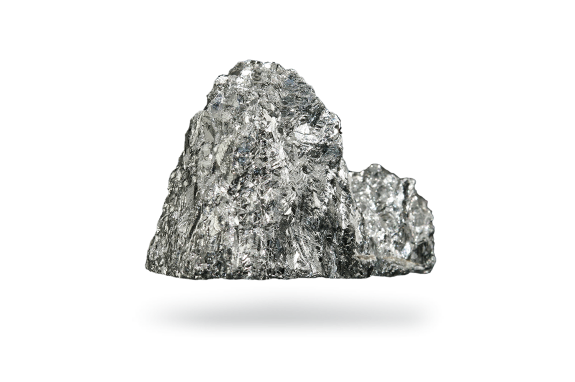

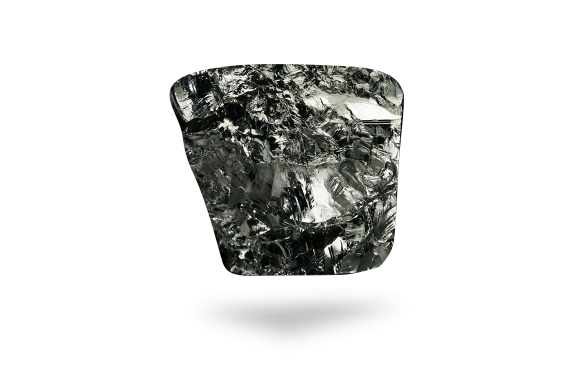

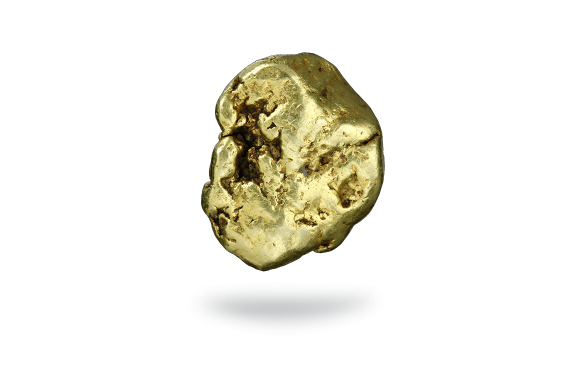

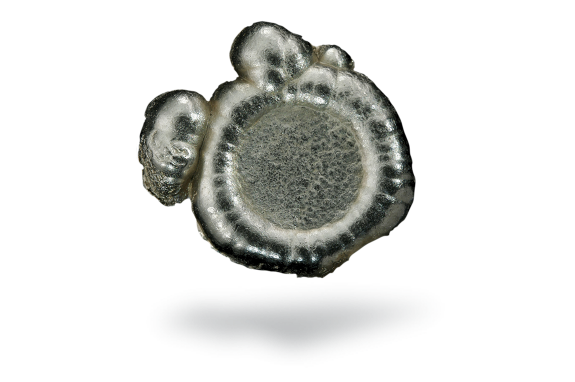

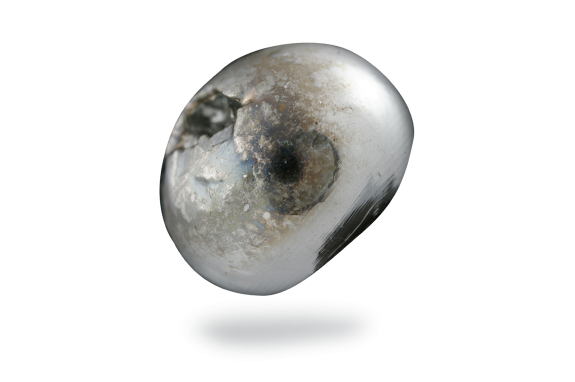

Did you know that molybdenum was once confused with and often utilized as though it were graphite? Like graphite, molybdenite can be used to blacken a surface or as a solid lubricant. It’s a silvery metal that lies between chromium and tungsten in Group 6 of the periodic table.

This element is central to life on our beautiful planet. You'll find tiny amounts of it in everything from the filaments in electric heaters to protective coatings in boilers. Its strong performance at high temperatures means that it has a range of commercial applications. For instance, molybdenum is considered an effective way of making steel harder and increasing its corrosion resistance.

Not only is it also very useful as a cold lubricant in engines such as those in motorcycles, but it is found in the enzymes in our body, too. Molybdenum-containing enzymes process foods such as cheese, wine and pickles. So think of this element when you enjoy your next glass of red wine on a Friday evening. Yet our bodies don’t need much of it. Humans can get by perfectly well with just one-third of gram for our whole life. Nonetheless, it is truly essential.

At least 50 molybdenum enzymes have now been identified in bacteria, plants, and animals. One of these important enzymes is nitrogenase, which allows nitrogen in the atmosphere to be absorbed and transformed into compounds that enable bacteria, plants, animals and humans to synthesize and utilize proteins. This metal is an essential element for all higher eukaryote organisms due to the variety of crucial reactions catalyzed by molybdenum-bearing enzymes, which are by far the most common bacterial catalysts used to break the chemical bond in atmospheric molecular nitrogen as part of the biological nitrogen fixation process.

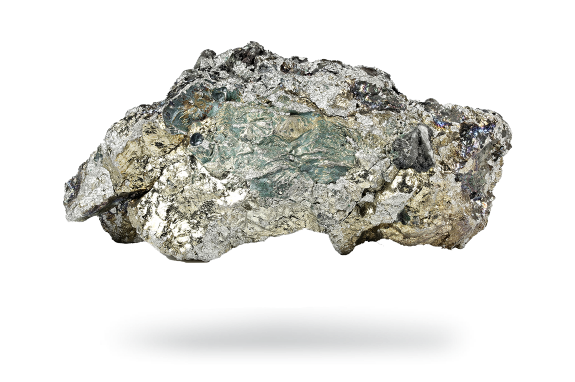

It is the 58th most abundant element but is spread fairly evenly in the Earth’s crust. Moybdenum is mostly sourced as byproduct of copper mining.

Applications

At Umicore, our specialty materials business division produces molybdenum carboxylate catalysts which are used in bottom-of-the barrel technologies, increasing the effectiveness of crude oil and petroleum. Molybdenum catalysts help reduce the average waste in the processes. This results in a drop in crude oil consumption, while the needs of society are still met.

We also use it for epoxidation catalysts. Molybdenum carboxylates can be included in the production of propylene oxide, which is a key base chemical in a variety of substances (e.g. polyols for polyurethane products such as insulation boards for housing).

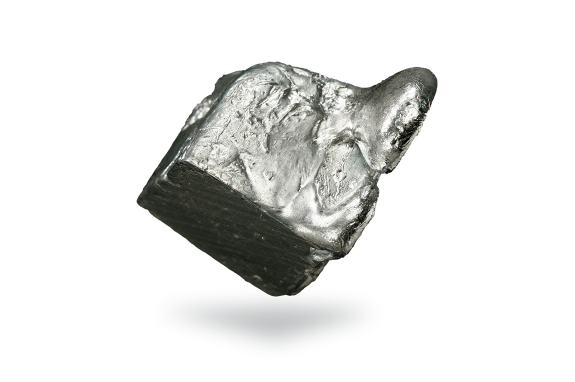

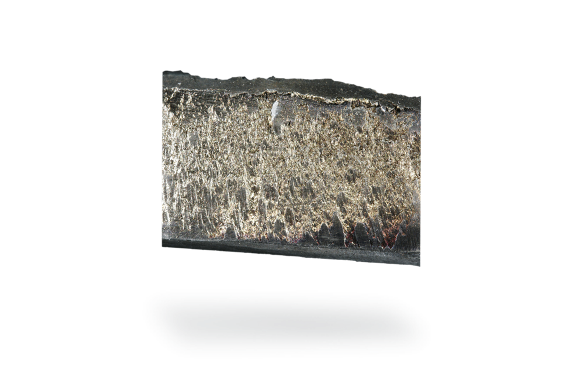

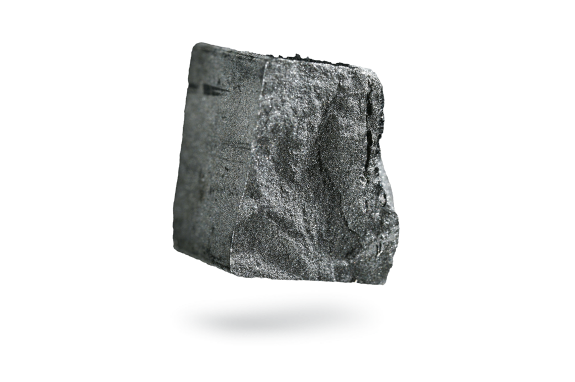

Most commercial molybdenum is used in the production of alloys, where it is added to increase hardness, strength, electrical conductivity and resistance to wear and corrosion. Small amounts of molybdenum can be found in a wide variety of products, including engine parts, drills, saw blades, electric heater filaments, lubricant additives, circuit board ink and protective coatings in boilers.

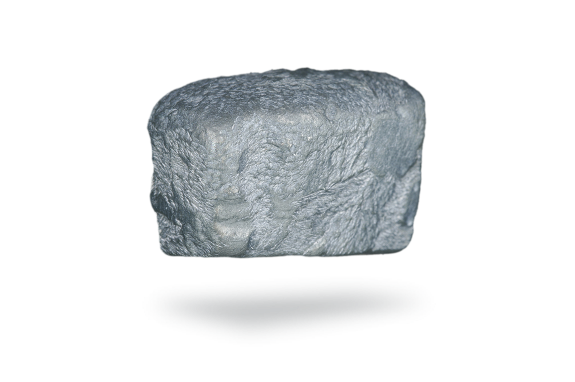

It is also used as a catalyst in the petroleum industry. Molybdenum is produced and sold as a gray powder, and many of its products are formed by compressing the powder under extremely high pressure. Due to its high melting point, molybdenum performs incredibly well at very high temperatures. It is particularly useful in products that need to stay lubricated at such extreme temperatures. So in cases where some lubricants and oils might decompose or catch fire, those containing molybdenum sulfides can deal with the heat and still keep things running smoothly.

Molybdenum serves primarily as an alloying agent in steel. When combined with nickel, however, it forms heat- and corrosion-resistant materials used in the chemical industry.

Properties

The name comes from the Neo-Latin term molybdaenum, which is based on the Ancient Greek word molybdos, meaning lead, since its ores were confused with lead ores.

Molybdenum is a shiny silvery-white metal that is ductile and highly resistant to corrosion. It has one of the highest melting points of all pure elements, together with tantalum and tungsten.;

History

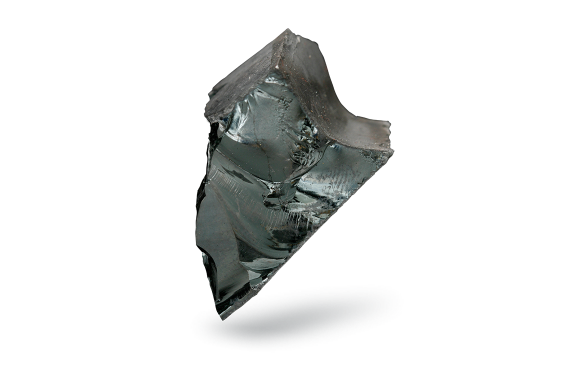

The soft black mineral molybdenite was often mistaken for graphite or lead ore until 1778, when an analysis by German chemist Carl Scheele revealed that it was neither one of these substances.

It proved to be very difficult to identify. Since no one had been able to reduce it to a metal, scientists continued to assume that molybdenite contained a new element.

Eventually, the element was identified by the Swedish chemist Peter Jacob Hjelm. He ground molybdic acid with carbon in linseed oil to form a paste. The paste allowed close contact between the carbon and the molybdenite. Hjelm then heated the mixture in a closed crucible to produce the metal, which he named molybdenum. The new element was announced in 1781.