Tantalum

Applications

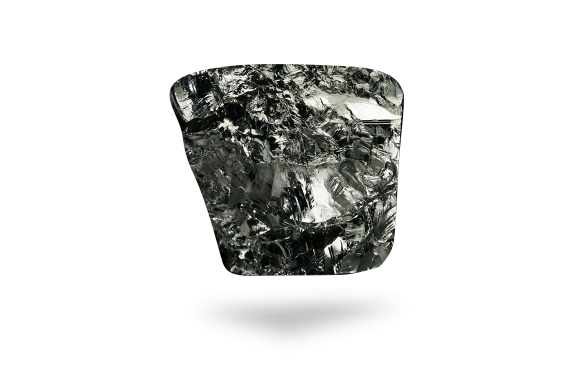

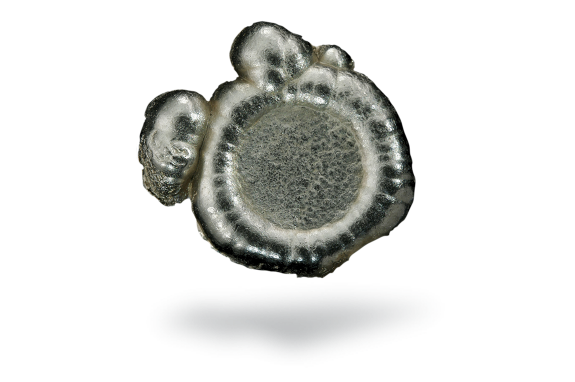

- Powders used in the manufacture of electrolytic condensers account for most of the metal consumed (about 60%).

- The carbide TaC, in association with tungsten carbide WC and titanium carbide TiC, is a component of hard metals for cutting and boring tools.

- Particularly suitable for heat exchangers; its thermal conductivity is high and its surface properties prevent the formation of adherent deposits.

- Manufacture of furnace components, such as screens, supports and crucibles.

- An alloying element in superalloys, of which it enhances the high-temperature strength.

- Being bio-inert, it is used for implants, pins, etc.

- Yttrium tantalate YTaO4 is used in medical diagnosis.

Recycling

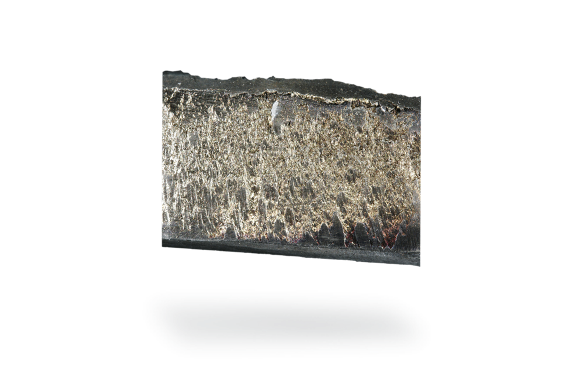

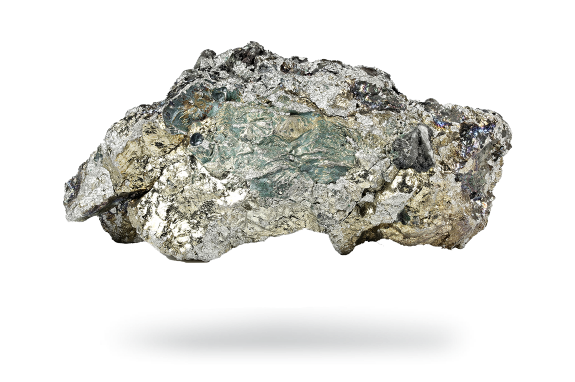

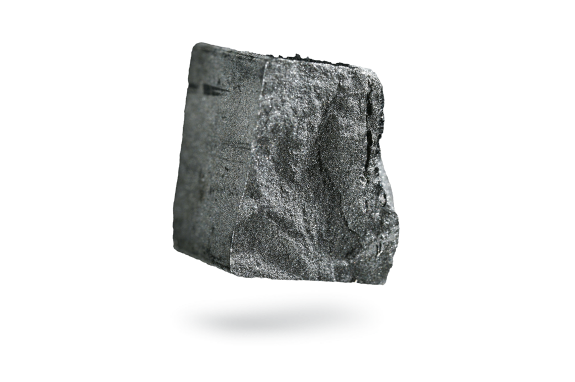

Tantalum is recovered from slags resulting from the smelting of tin. It is also recovered from powder sweepings and wire scrap from capacitor manufacturing, from end-of-life capacitors and spent sputtering targets

Properties

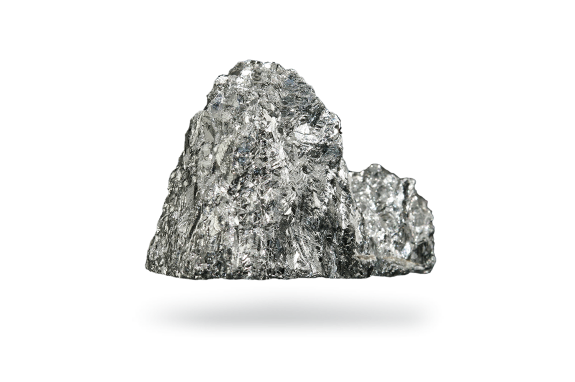

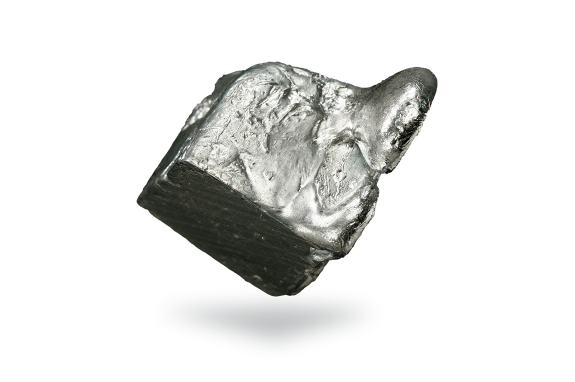

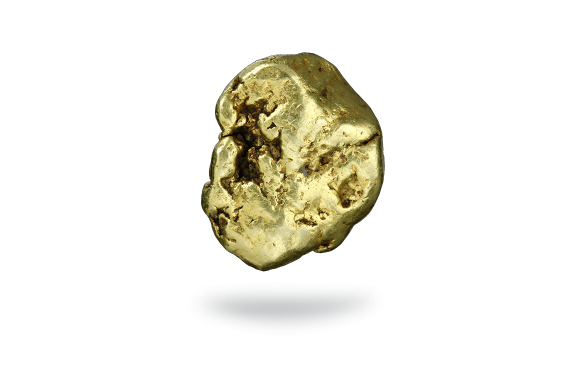

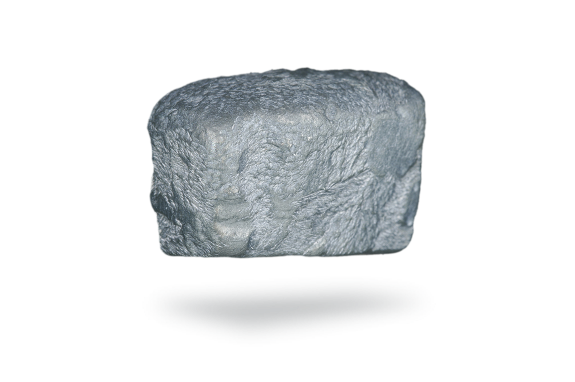

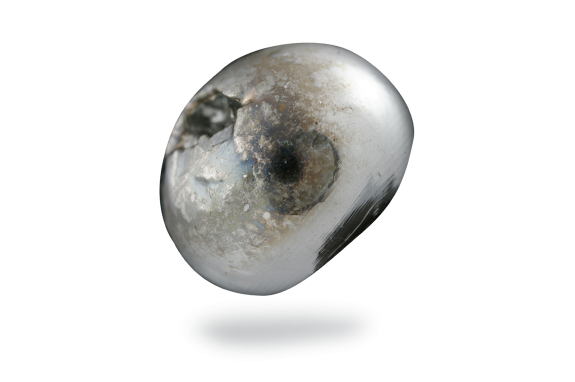

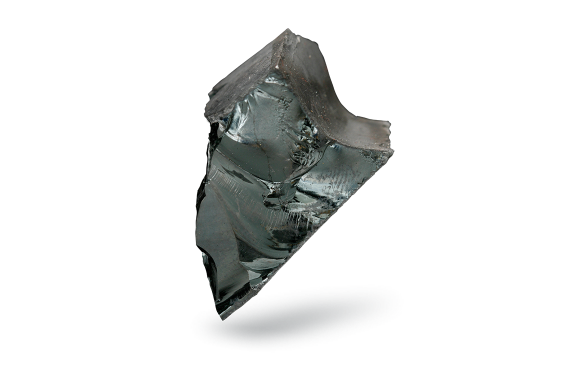

- A very heavy, ductile bluish-grey metal.

- A good conductor of heat and electricity.

History

Ekeberg isolated tantalum from Swedish ores in 1802 and gave it its name, that of the son of Zeus and the father of Niobé. Separation from niobium, with which it is always associated in ores, proved very difficult, being achieved by Marignac only in 1866.

In 1903 von Bolton succeeded in producing tantalum powders by reduction of the double tantalum–potassium salt K2TaF7 with sodium. In the same year Siemens and Halske developed the first incandescent lamps in which a tantalum filament was substituted for the traditional carbon filament. In 1907 the same scientists used tantalum in rectifiers.

Tantalum sheets for the chemical industry were introduced around 1930.