Nickel

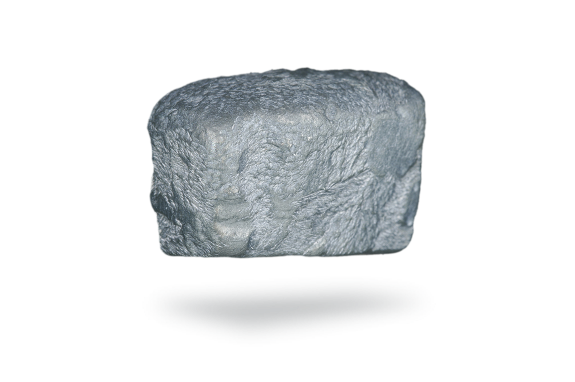

Did you know that nickel is an element that cannot be destroyed nor created ? This makes it an excellent metal for Umicore's closed loop business philosophy and – more general – the principle of circular economy, namely keeping materials as long as possible in the value chain. The characteristics of nickel, such as corrosion resistance, high-temperature stability, strength, flexibility, toughness, recyclability, as well as catalytic and electromagnetic properties, contribute towards the creation of sustainable products and technologies. Nickel in its various forms plays hundreds of roles in thousands of products and applications we use every day.

At Umicore, we use nickel mainly as an active material in Li-ion rechargeable batteries. These batteries power our smartphones, e-bikes, and in particular electrical vehicles.. Nickel is all around us. Recycling nickel from old batteries is of course another way in which Umicore comes in contact with this metal.

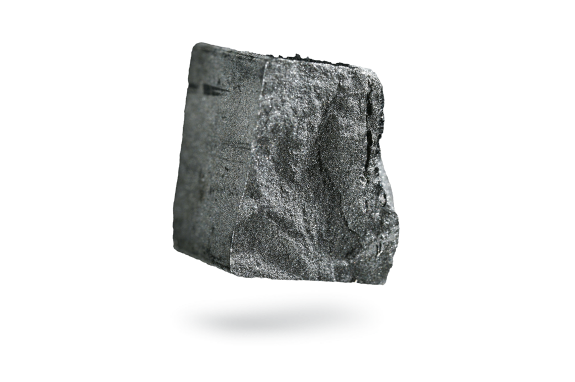

The main application of nickel today can be found in austenitic stainless steel, using around 70% of all newly mined nickel. It is used mainly in the chemical industry, mechanical construction, architecture and household equipment such as cutlery, sinks, and pans.

Thin nickel layers are also used for decorative or anti-corrosion purposes, or as a substrate for a thin layer of chromium, which you can see in taps, stopcocks and fittings, or gold for jewelers and electronics.

Nickel-containing cupro-aluminums exhibit excellent resistance to corrosion in seawater and are used to make propellers, pumps, sluice gates, etc.

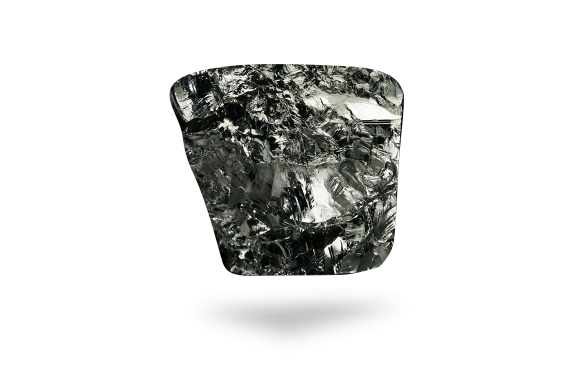

Recycling

Like many other metals, nickel is fully recyclable. It can be recycled over and over again without loss of quality and therefore perfectly fits the Circular Economy (CE) model.

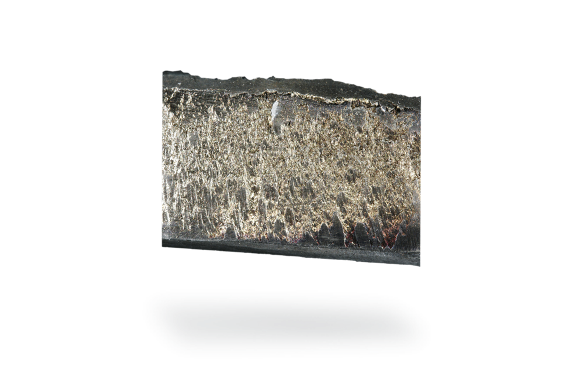

Most nickel recycling done today is linked to the stainless steel industry. It is standard practice to recycle special alloys into the same special alloy wherever possible; the stringent specifications and the cost of achieving these special alloys justify the closed loops within the steel industry.

Umicore developed the technology and expertise to recycle nickel from spent rechargeable batteries.

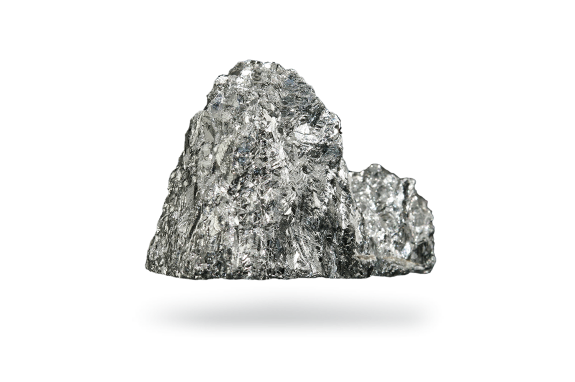

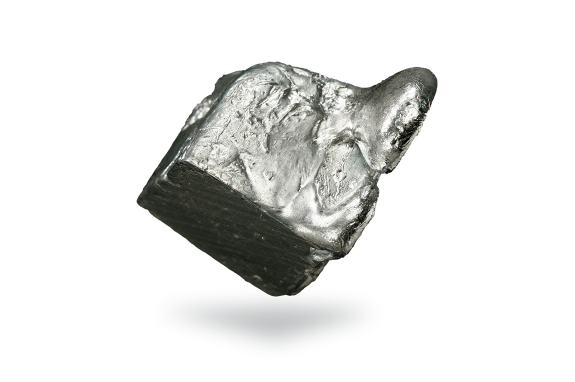

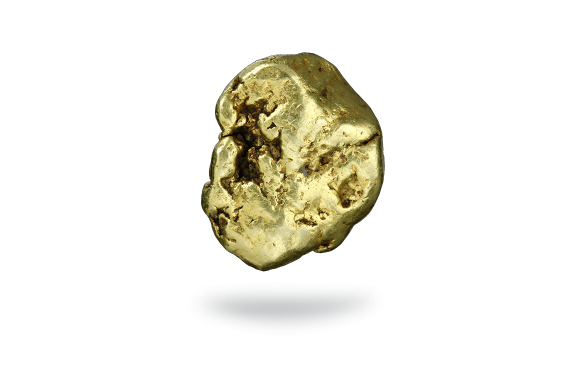

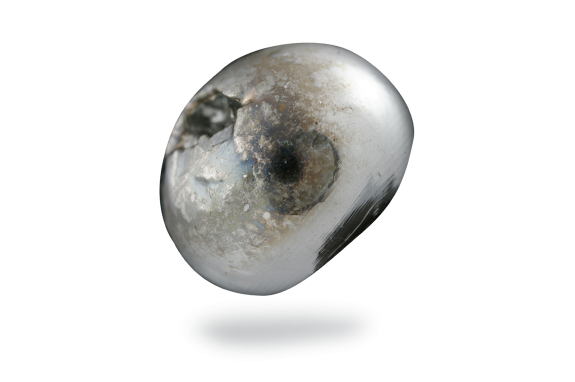

Properties

Nickel, the 5th most common element, is a silver-grey metal that is hard, tough, malleable and flexible. It is found extensively in the earth’s crust and core. It is ferromagnetic which means it can become magnetized when exposed to an external magnetic field. This is especially useful when mixed with the right metals because it creates super alloys, materials that keep their strength during high stress and high temperatures. This is a good property for jet engines for example. Its electrical conductivity is about one-sixth of that of copper. Nickel is also used as a carrier metal for platinum group metals.

History

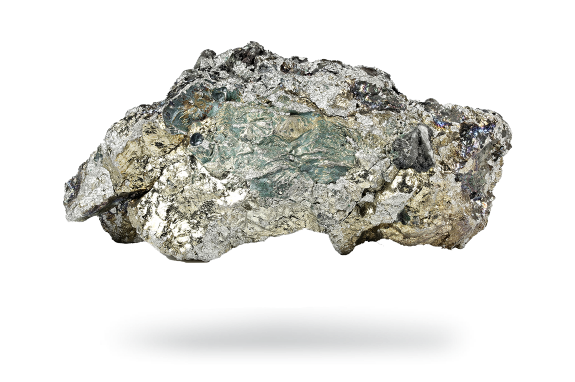

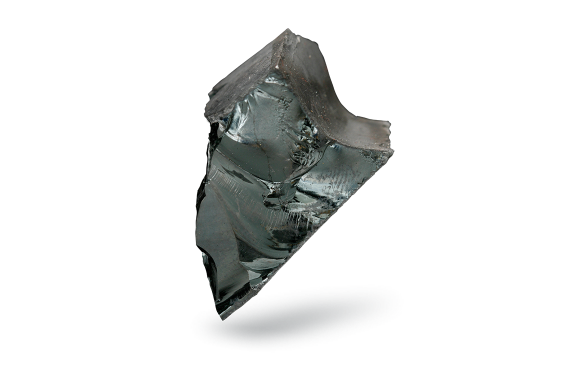

Throughout the Middle Ages miners in Germany occasionally found a brownish-red ore, which they called kupfernickel. Miners thought they had found copper ore but could not get the copper out, so the name suggested it was the devil’s copper. ‘Old Nick’ was a 17th century term for the devil. The Swedish scientist Cronstedt managed to isolate the metal in 1751 and named it nickel.

Did you know that the U.S. five cent coin, best known as the "nickel", is composed of 75% copper and only 25% nickel? Nickel only began to arouse real interest when the US started to use a Cu-Ni alloy for its coins. Many coins nowadays, including the Euro coin, contain nickel, and coin makers are now moving to nickel plated steel, particularly for lower valued coins.

Around the end of the 19th century, nickel found its way into the shipbuilding and armor plating professions. Its use also grew steadily in the development of stainless steel, which currently accounts for more than 70% of nickel consumption.