No dislocations

Umicore germanium has zero etch pitch density (EPD), which results in improved yield and long-term device reliability. The burn-in of final devices may be reduced.

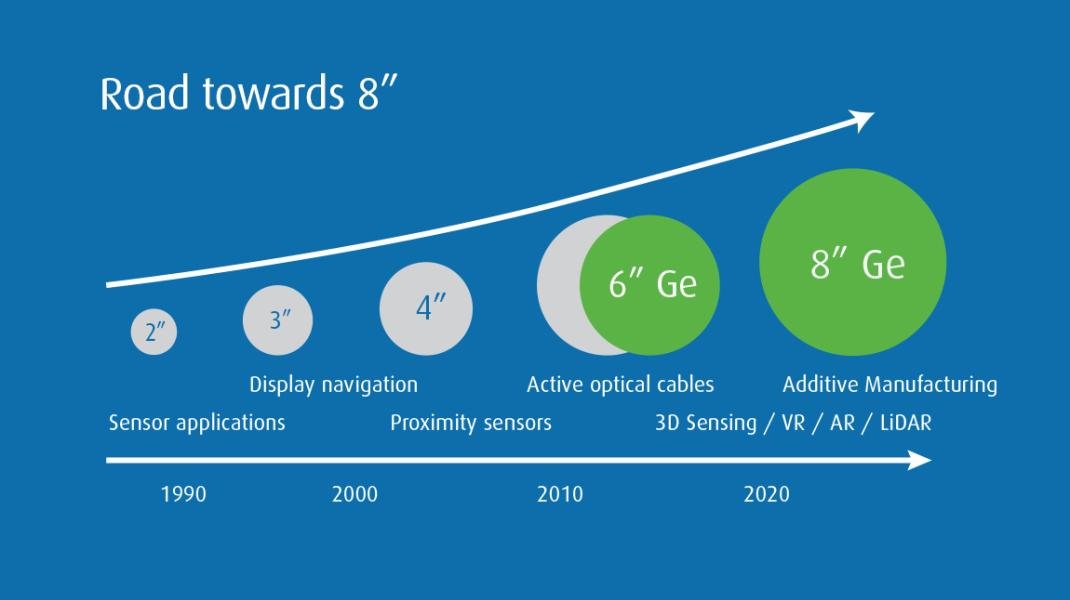

8" capabilility

An increase in wafer size has always been a key driver of capacity growth. As markets expanded, they required larger-diameter wafers: progressing consecutively from 2" to 3", 4", and ultimately 6".

Migrating GaAs to 8" remains a significant challenge. This is where 8" germanium provides a viable solution. The true benefit of moving to larger wafer diameters lies in achieving lower processing costs.

P and n-type germanium possible

Unlike GaAs, germanium allows for both p-type and n-type use, enabling alternative VCSEL designs.

More design freedom than GaAs

Germanium and GaAs wafers exhibit similar levels of resistivity. Although n-type GaAs offers higher mobility, germanium permits greater doping levels (pending Umicore patent). Unlike GaAs, p-type germanium has resistivity comparable to that of n-type, which provides more flexibility for alternative VCSEL designs.

Germanium wafers can be manufactured to be significantly thinner due to their lower brittleness, which enhances thermal performance. For example, a 6" Ge wafer used in photovoltaics typically measures 225 µm in thickness. This reduced thickness lessens or even eliminates the need for back grinding, ultimately improving end-of-line yield.

Twice as strong as GaAs

Germanium compared to Silicon and GaAs

Property |

Silicon |

GaAs |

Germanium |

|

| Crystal Structure | Diamond | Zinc blend | Diamond | Si and Ge are elemental semiconductors with similar large (12") diameter 0 EPD* cyrstal processes |

| Density (g/cm³) | 2.33 | 5.32 | 5.33 | |

| Lattice constant (Å) | 5.430 | 5.653 | 5.658 | Ge and GaAs are lattice matched |

| Bandgap energy at 300K (eV) | 1.12 | 1.42 | 0.66 | |

| Electron mobility (cm²/V-s) | 1350 | 8500 | 3900 | Ge has both high electron and hole mobility |

| Hole mobility (cm²/V-s) | 480 | 400 | 1900 | |

| Melting point (°C) | 1415 | 1238 | 937 | |

| Thermal expansion (1/°C) | 2.6 10-6 | 5.7 10-6 | 5.9 10-6 | Ge and GaAs have similar thermal expansion |

| Thermal conductivity (W/cm°C) | 1.3 | 0.55 | 0.55 | |

| Fracture thoughness (MPa.m1/2) | 0.8 | 0.31 | 0.66 - 0.72 | Ge is twice as tough as GaAs |

* EPD: Etch pitch density, dislocation density